– Capacity Planner,

Fortune 500 Financial Institution

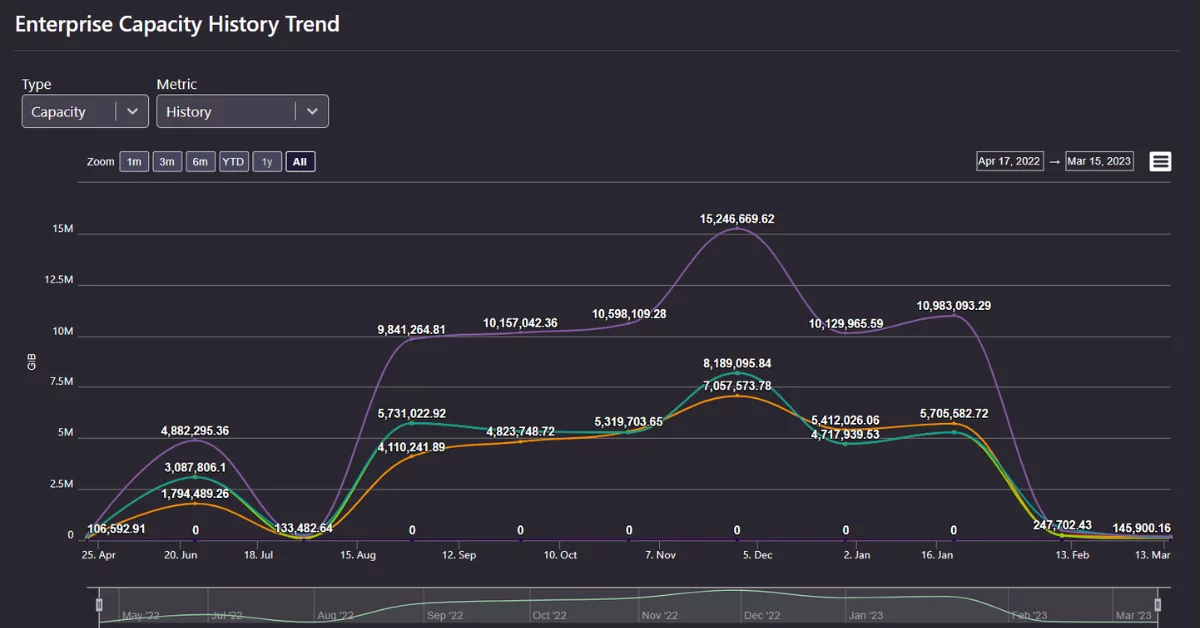

To perform effective capacity planning for 300 PB of storage, this two-person team needed faster, more accurate historical data from their devices. Although they used a management tool to collect this data from their multi-vendor storage environment, the process was difficult and time-consuming.

Meanwhile, using the data required them to build and maintain tedious spreadsheets, each separately designed for specialized tasks like forecasting.

“It took a good two weeks just to do monthly reports,” said one of the capacity planners. That left less than half the month to accomplish anything else.

After implementing Visual One Intelligence®, the team was thrilled to see that data from all their devices and vendors could be ingested and analyzed together, with no need for external management. They could generate any of the 60+ reports in just a few clicks.

Tasks that seemed impossible in Excel – like change forecasting and volatile trend modeling – are accessible in minutes on Visual One Intelligence®’s® dashboard.

By using Visual One Intelligence®, the team gained back more than a week per month in reporting time to use on new projects that would move the organization forward.

“Including the efforts needed to maintain our prior tool’s infrastructure, we saved an entire FTE,” said one capacity planner, “plus significant cost savings between the tools.”